Stop thinking about limits and start discovering possibilities.

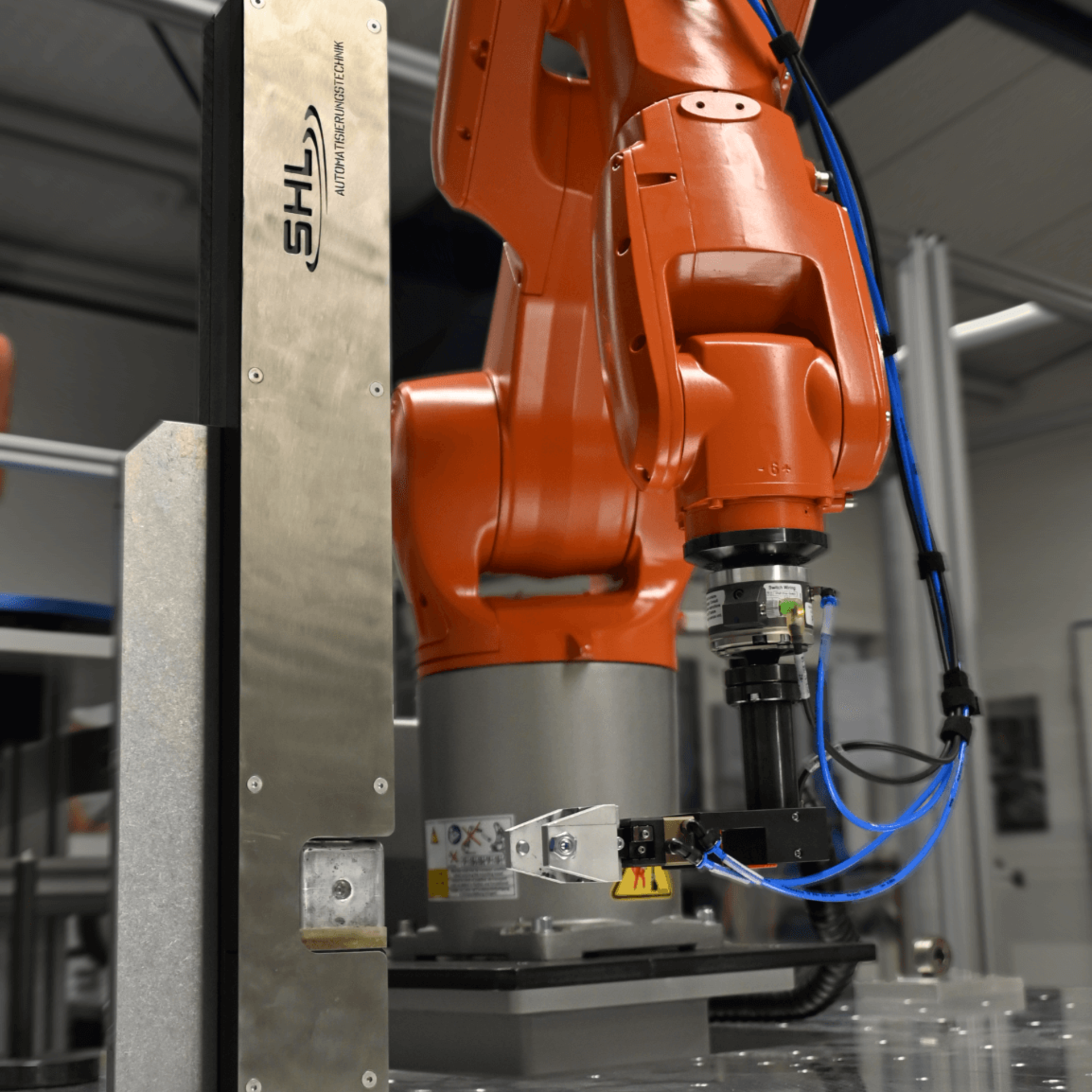

Technical know-how is an important success factor for your company - and thus an important part of your personnel and company development. Even with automated grinding, polishing and deburring processes, maximum efficiency and quality does not depend solely on the machine, system, production line or transfer line: it must also be optimally operated. Your employees can learn that from us, because we have set up a state-of-the-art training center especially for this purpose.

Furthermore, training on the mobile training cell or the SHL system is also possible. In addition to the three standard training courses for the robots KUKA, Fanuc and ABB, individual training courses are also possible.

Please sign in for KUKA training here

Training program

Basic training

Seminar contents:

- Safety instruction for robots and grinding, polishing and deburring applications.

- Grinding: Selection of suitable grinding tools, process parameters

- Polishing: Selection of suitable polishing tools, process parameters

- Deburring: Selection of suitable deburring tools, process parameters

- Simple options for quality assurance in the area of grinding, polishing, deburring

- HMI: use of the SHL user interface, setting of various process parameters

- Manual operation of the robot

- Basic robot functions for KUKA , FANUC , ABB robots

- Languages: German or English

Robot programming 1 for grinding and polishing applications

Seminar contents:

- Safety instruction for robots and for grinding, polishing and deburring applications

- Operation of a robot cell

- Basics of robot commissioning

- Creation of simple linear work programs

- Data security/data maintenance

- Dealing with malfunctions

- For KUKA, FANUC and ABB robots

- Languages: German or English

Robot programming 2 for grinding and polishing applications

Seminar contents:

- Safety instruction for robots and for grinding, polishing and deburring applications

- Operation of a robot cell

- Creation of work programs with various subroutines

- Variables and calculations in grinding and polishing programs

- Simple palletizing programs

- Using logical functions in the robot program

- For KUKA, FANUC, ABB robots

- Languages: German or English

KRC4 / KRC5

Programming 1

Seminar contents:

- Safety instruction for robots and for grinding, polishing and deburring applications

- Operation of a robot cell

- Basics of robot commissioning

- Creation of simple linear work programs

- Data security/data maintenance

- Dealing with malfunctions

- Languages: German or English

KRC4 / KRC5

Programming 2

Seminar contents:

- Safety instruction for robots and for grinding, polishing and deburring applications

- Operation of a robot cell

- Creation of work programs with various subroutines

- Variables and calculations in grinding and polishing programs

- Simple palletizing programs

- Using logical functions in the robot program

- Languages: German or English